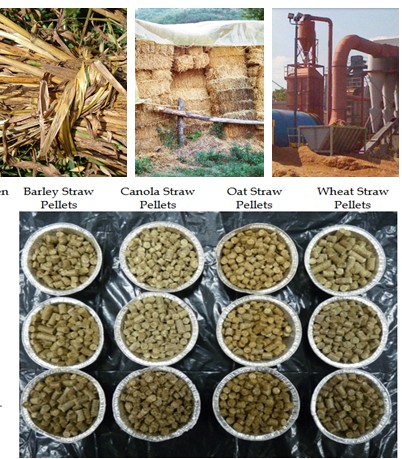

Common Crop Stalk & Straw for Making Pellets

As we all know, straw materials such as wheat straw, rice husk, corn straw, sorghum, peanut straw, soybean straw, alfalfa straw and cotton stalk etc. are a byproduct of crops and not generally used after the crop is harvested. It is clear that we need to make better use of straw materials which are common in the fields to save energy. Making pellet fuel from the stalks is an environmental friendly solution for heating fuel. During recent years straw pellets have increased tremendously in popularity as a heating fuel, with many homeowners and commercial facilities choosing pellet stoves or boilers over traditional wood-fired equipment.

How to Make Stalk & Straw Pellets

◆ Feedstock grinding:Turn on the hammer mill.Feed dried crop stalks that moisture content is 8%-15% one at a time into the hopper of the hammer mill. It will exit the machine in a shredded mass.

◆ Moisture control: Add water if necessary to moisturize the shredded crop stalks. You should add modest water so that the pellets are shiny and hard. If there is not enough moisture, the shredded stalks will not feed into the pellet mill properly. If there is too much moisture, no pellets will come out.

◆ Extrusion:Turn on the pellet mill. Wait until it warms up to the right temperature. Feed the shredded crop stalks into the hopper of the pellet mill. In a few seconds the pellet mill will press the crop stalks into pellets.

◆ Cooling and Packaging

Collect all the pellets in the container and allow them to cool at a temperature 3~5℃ above ambient temperature to reduce the material temperature and moisture content. So the fuel pellets are more convenient to package, transport and store.Then store them in sealed bags and prepared for using.

Advantages and Further Market of Crop Stalks Pellets

Stalks fuel pellets are generally a superior fuel when compared to their raw feedstock.The moisture content of pellet fuel is lower and more uniform, and it produces more heat per unit of weight,making it a more efficient fuel. Not only are the pellets more energy dense, they are also easier to handle and use in automated feed systems. Meanwhile they are cleaner and take less space to store.These advantages,when combined with the sustainable and ecologically sound properties of the fuel, make it very attractive for use. Many people are not familiar about the biomass pellet fuel, but it doesn’t have a wide use now. Biomass pellet fuel use is approved by the community, and very low-carbon, is very good as a new energy. Biomass fuels can use for home heating, central air conditioning in hotel, industrial boilers and thermal power plant fuel. This fuel is a new national energy development project, and it has a low-carbon, energy-saving, environmental protection and the advantage of reusing. So why don’t we choose it?