The Diesel Flat Die Wood Pellet Mill Overview

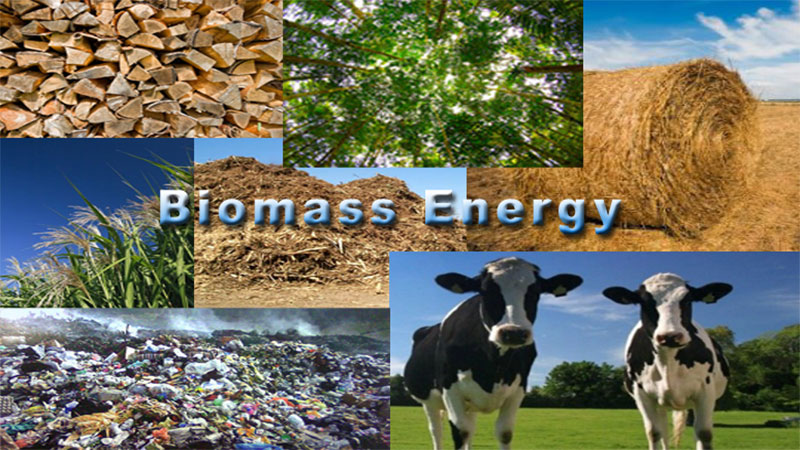

With the utilization of biomass energy, flat-die wood pellet mills have become increasingly popular. It can convert waste biomass materials into wood pellets. The final wood pellets can be burned as green fuel in a pellet stove or boiler. Diesel flat die pellet mill is one of the most popular equipment in the pellet production field, which is especially suitable for small-scale industrial production in areas with a shortage supply of electricity.

The diesel flat die pellet mill is a versatile and powerful pellet machine designed to convert a wide range of biomass materials into high-quality pellets. Unlike electric pellet mills, this model is powered by a reliable diesel engine, making it an excellent choice for areas without access to electricity or where portability is essential.

Its compact and user-friendly design ensures that even first-time users can operate it with ease. The diesel flat die pellet machine is built with durability in mind, featuring robust construction and wear-resistant components to ensure long-term, efficient performance. Whether you’re looking to produce animal feed pellets or renewable biomass fuel, the diesel flat die pellet mill offers a cost-effective, eco-friendly solution tailored to meet your needs.

The Features of Flat Die Wood Pellet Mill With Diesel Engine

The diesel flat die pellet mill boasts various features that make it a reliable, efficient, and versatile solution for pellet production.

1. Diesel Engine Powered

It operates independently of electricity and is ideal for remote or off-grid locations. Equipped with a high-performance diesel engine for consistent power output. Low fuel consumption ensures cost-efficiency, especially in rural areas with a shortage supply of electricity.

2. Compact and Portable Design

Lightweight and easy to move, perfect for both indoor and outdoor use. Designed for convenience, allowing you to set it up wherever it’s needed, making small-scale pellet production possible.

3. Robust Construction

Built with high-quality, wear-resistant steel to ensure durability and longevity. Engineered to handle heavy-duty operation and extended use without compromising performance.

4. Versatile Raw Material Compatibility

Processes a wide variety of biomass materials, including Sawdust, wood shavings, and wood chips. Agricultural residues such as corn stalks, wheat straw, and rice husks. Grass, leaves, and other organic materials.

5. Adjustable Pellet Sizes

Allows customization of pellet diameter to meet diverse needs (e.g., animal feed or biofuel). Comes with interchangeable flat dies for different pellet sizes. Adopt a screw-center adjusting pressure structure, making a flat die pellet mill more practical.

6. Efficient and Reliable Performance

A high compression ratio ensures consistent pellet quality. Designed for maximum output with minimal waste. Equipped with the clutch and accelerating-decelerating device to change its speed.

7. Easy to Operate and Maintain

User-friendly controls and a straightforward pelletizing process. Visible chamber design makes the pelleting process clear and visible, making it convenient to solve problems quickly. Minimal maintenance requirements due to its simple mechanical structure. Easy access to components for cleaning and part replacement.

CONTACT US FOR A FREE QUOTE

Applications of the Diesel Flat Die Pellet Machine

The diesel flat die pellet mill is a versatile machine with applications across various industries and settings. Its ability to process diverse raw materials makes it an indispensable tool for creating high-quality pellets for a range of uses. It is ideal for remote areas, disaster-stricken regions, or locations without consistent access to electricity. The diesel flat die pellet mill empowers farmers, small businesses, and eco-conscious individuals to convert raw materials into valuable pellets for various uses, promoting sustainability and cost efficiency.

1. Wood Pellet and Biomass Pellet Production.

Biomass Pellet Production: Transforms agricultural residues (e.g., straw, rice husks, and corn stalks) and forestry waste (e.g., sawdust, wood chips, and bark) into efficient biomass pellets.

Heating and Cooking Fuel: Produces eco-friendly fuel pellets for use in stoves, heaters, and boilers, providing a sustainable alternative to fossil fuels.

2. Agriculture and Livestock Pellet Production

Animal Feed Production: Converts raw materials like corn, wheat bran, and soybean meal into nutrient-rich pellets for livestock, poultry, and aquaculture. Offers customizable pellet sizes to suit the dietary needs of different animals.

Fertilizer Pellets: Processes organic materials such as manure into pelletized fertilizers for easy handling and application.

3. Small-Scale Commercial Use

Pelletizing for Sale: Enables small businesses or cooperatives to produce and sell biomass fuel or animal feed pellets locally, creating an additional revenue stream.

4. Household Use

Home Heating: Produces pellets for personal use in pellet stoves, reducing heating costs and reliance on non-renewable energy sources.

Garden Fertilizer: Convert yard waste like grass clippings and leaves into fertilizer pellets.

Why Choose Our Diesel Flat Die Pellet Mill?

Our diesel flat die pellet mill stands out as a reliable, efficient, and versatile solution for all your pelletizing needs.

1. Superior Quality and Durability

Built with premium-grade materials, ensuring long-lasting performance even under heavy-duty use.

Equipped with wear-resistant components designed to handle continuous pelletizing operations without compromising quality.

2. Highly Efficient Performance

Powered by a robust diesel engine that ensures consistent performance. High compression ratio for producing dense, uniform pellets with minimal waste.

3. Versatility in Applications

Handles a wide variety of raw materials, including wood waste, agricultural residues, and organic matter.

Produces pellets for diverse uses such as animal feed, biomass fuel, and organic fertilizer.

Offers customizable pellet sizes, making it adaptable to different needs.

4. Portable and Convenient Design

Compact and easy to transport, allowing you to use it wherever needed—indoors or outdoors.

A simple setup and user-friendly operation ensure anyone can use it with minimal training.

5. Cost-Effective and Sustainable Solution

Eliminates reliance on electricity, saving operational costs, especially in remote areas.

Converts waste materials into valuable products, contributing to environmental sustainability.

6. Comprehensive Customer Support

Comes with a detailed user manual and optional installation guidance for a smooth start.

Backed by responsive customer service for troubleshooting and technical assistance.

Spare parts and maintenance kits are readily available for long-term reliability.

7. Proven Track Record

Trusted by farmers, small businesses, and eco-conscious individuals around the world.

Positive feedback and success stories from satisfied customers underscore its effectiveness and reliability.

8. Competitive Pricing and Value

Offers an affordable entry point to high-quality pellet production.

Designed to provide the best return on investment with its durability and efficiency.

Diesel Flat Die Wood Pellet Mill Technical Data

|

Model

|

Power (HP) |

Capacity

(Wood pellets) |

Flat die Dia.

(mm) |

Dimension

(mm) |

|

PLM120D

|

8

|

40-60 kg/h

|

120

|

550*300*710

|

|

PLM200D

|

15

|

110-140 kg/h

|

200

|

850*420*850

|

|

PLM300AD

|

30

|

220-280 kg/h

|

300

|

1200*520*1050

|

|

PLM300BD

|

35

|

250-300kg/h

|

300

|

1200*520*1050

|

|

PLM350AD

|

55

|

300-360 kg/h

|

350

|

1270*580*1150

|

|

PLM400D

|

55

|

400-500kg//h

|

400

|

1350*600*1200

|

CONTACT US FOR A FREE QUOTE

Tips For Using a Diesel Flat Die Wood Pellet Mill

◆ Please carefully read the operation instructions and follow the technician’s professional guidance before start running.

◆ Check the easy-wear parts and other components regularly to ensure normal operation.

◆ Avoid overloading production to guarantee a long service life of the equipment.

◆ Select a suitable compression ratio according to different materials to improve capacity and reduce wear.