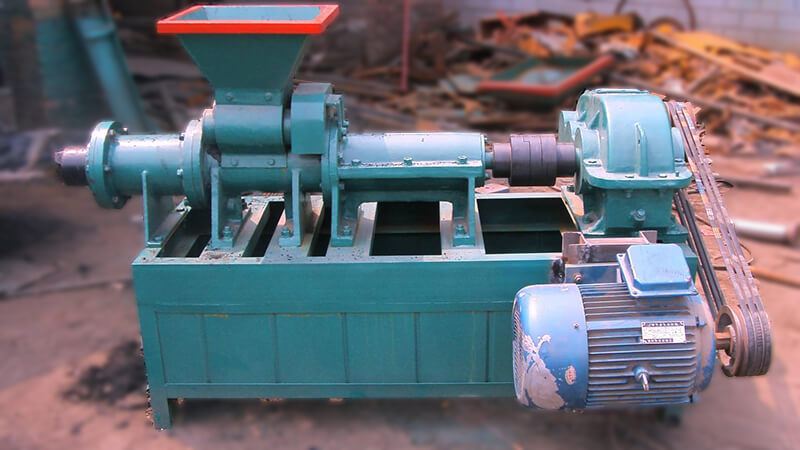

The biomass briquette machine is designed to press loose biomass residues, such as sawdust, rice husk and straw etc., into high density solid blocks that can be used as a fuel. This new generation charcoal briquette machine can make the briquettes more solid with a more smooth surface.

Materials for Biomass Briquetting

The best materials for biomass briquetting are sawdust and other woody residues, because they contain a high proportion of lignin. However, most dry agricultural residues can be used if they are ground into powder. The materials include cornstalks, wheat straws, cottonseed hulls, rice straws, rape straws, beanstalks, herbages, alfalfas, peanut vines, peanut shells, sweet potato vines, fire woods, branches, wheat husks, furfural residues, reeds and bamboo threads etc.

New Generation Charcoal Briquette Machine Features and Advantages

★High efficiency, low power consumption and good molding effect.

★The material size should be less than 3mm, and the moisture content should be about 12%.

★Adopt oil-immersed structure, the briquette press has a long working life.

★ No binder is needed in the briquetting process.

|

Before carbonization |

After carbonization |

The Future of Biomass Briquetting

Wood briquettes have been used as fuel by more and more people because they can be used in automated boilers for space heating, also it can be used for industry use. In many countries there are significant resources of biomass residues, which are not needed for agriculture. Thus as the cost of conventional fuels increases, the use of biomass briquettes and pellets is likely to grow. So biomass briquetting is an ideal choice for investment.