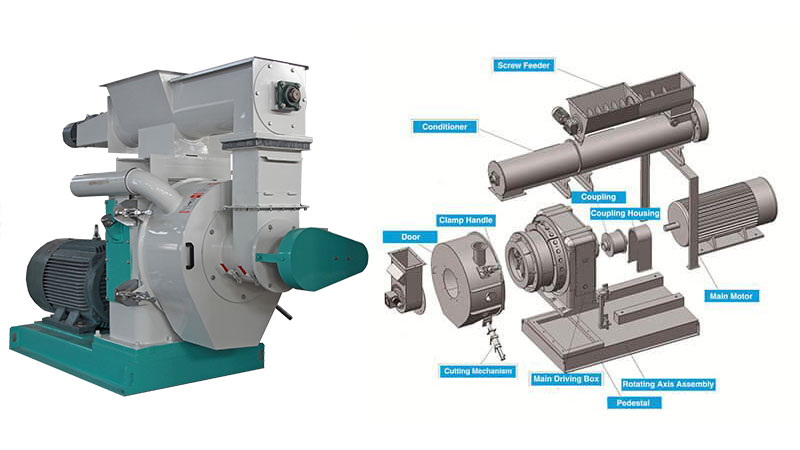

Ring die wood pellet mill is specialized in making the wood pellets from all kinds of sawdust, straw, forestry wastes, wood chips and other agricultural waste materials. It is identifiable by the circular “ring” shape of their extrusion. As an important part which decides the quality of the wood pellet, it is critical to choose proper ring die for the wood pellet mill. The following are instructions to choose the ring die.

1. Choose the ring die according to the raw materials you use. Different raw materials requires different die holes, porosity and compression ratio, so when choosing the ring die of wood pellet mill, raw materials should be taken into consideration.

2. Look for the materials ring die used and its processing procedure . Ring die usually made from carbon structural steel, alloy structure steel or stainless steel and through machining, drilling, heat treatment and other process, the raw materials are made into ring die. Good quality ring die should adopt vacuum heat treatment.

3. Pay attention to the shapes of the die hole. There are different shapes of die holes such as straight type hole, stepped hole, outer cone hole and inner cone hole. Straight holes and stepped holes are suitable for mixed feed pellet processing, outer cone holes are available for high-fiber feeding pellet.

4. The roughness of the die hole also influences the quality of the ring die. If the roughness is too high , the quality of the pellets will be poor. The die holes of ring die drilled by gun-drill will be more smooth.

5. Choose proper compression ratio of ring die. The wood pellets made by ring die with high compression ratio is with higher density and more smooth surface. Customers can choose different compression ratio according to the different requirements of the wood pellets.