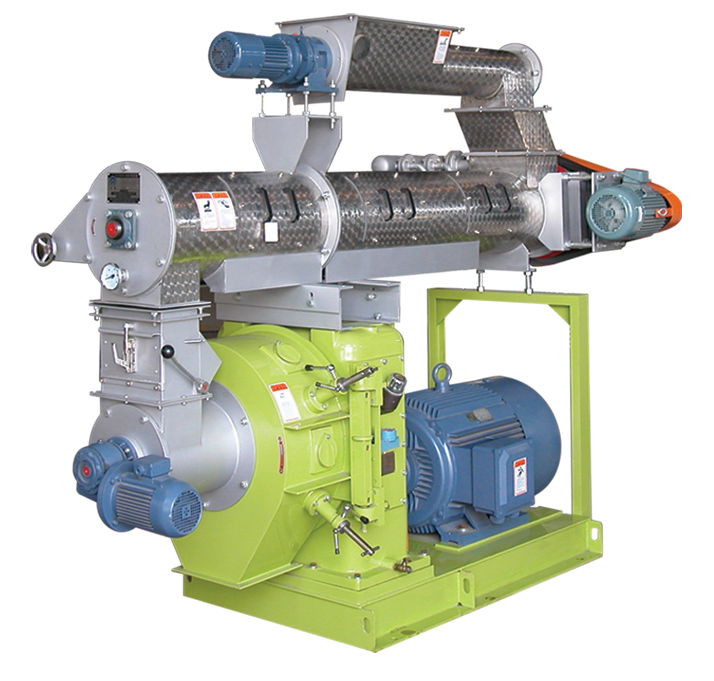

As you would expect, there are various different types and designs of wood pellet mill. Of course, each design has its own advantages and disadvantages. In general, the two main types of wood pellet mills are the flat die pellet mill and the ring die pellet mill.

Now I’d like to introduce the working principle of flat die pellet mill for you. As you can see, a solid metal plate is sitting below a series of compression rollers. Material enters from above and falls between the rollers, which is then compressed through the die. The finished pellets then emerge from the base of the die and leave the pellet mill.

This kind of flat die pellet mill is always used for the small-scale production of animal feed. The same feed pellet mills are often promoted as wood pellets.

In conclusion, both flat die pellet mill and ring die pellet mill have their advantages. However, what kind of pellet mill is more suitable than the other depends on your raw material. Any question, please feel free to contact us Amisy Group as soon as possible.